| A Maturity Model for Digital Twins in the Industrial Metaverse | |

| Date of publication:2022-11-16 Reading times:490 字体:【大 中 小】 | |

1. Analysis of digital twin maturity assessment requirements As an effective means to realize cyber-physical integration, digital twin has been widely concerned and highly valued by domestic and foreign academic circles, government departments and people in related fields. In recent years, the author’s team focused on digital twin five-dimensional model, digital twin model construction theory, digital twin multi-scale modeling method, digital twin model evaluation index system, digital twin data, digital twin service, digital twin standard system, digital twin enabling Technology and tools have carried out exploratory theoretical research work, and a series of practical work has been carried out focusing on digital twin workshops, digital twin equipment, and digital twin satellites. However, in the process of communicating and discussing with domestic and foreign scholars, government departments and enterprises in related fields, we found the following common questions and confusions: (1) How to judge whether it is a digital twin? (2) How to judge whether the existing digital twin can meet the application requirements? The above problems can be attributed to the lack of a systematic description and evaluation method for the digital twin category and development stage , while the maturity model is a systematic description of the concept category, development process and staged goals of the target system. At the same time, it also has the ability to evaluate A function of the target system’s current level of development and capability. Therefore, from the perspective of landing application, this paper proposes a set of digital twin maturity model, and designs a set of digital twin maturity evaluation application process. 2. Digital twin maturity level Statistical analysis of existing theoretical research and application practices related to digital twins can be mainly divided into the following categories according to their functions and uses: ① physical entity design verification and equivalent analysis based on digital twins ; ② visualization of physical entity operation process based on digital twins Monitoring ; ③Remote operation and maintenance management and control of physical entities based on digital twins ; ④Diagnosis and prediction based on digital twins ; ⑤Intelligent decision-making and optimization based on digital twins ; Through the common analysis of the above-mentioned various types of digital twin research and applications, it is found that physical entities, digital twin models, and the connection and interaction between them constitute the “minimum concept” of digital twins. On this basis, based on the five-dimensional digital twin model proposed by the author’s team earlier, from the physical entity (PE), digital twin model (DM), digital twin data (DD), connection interaction (CI) and functional service (FS) five Starting from this dimension, according to the connection interaction mode and the degree of automation, taking the functional services that digital twins can provide as the main line, digital twins are divided into six maturity levels, as shown in Figure 1. Among them, the physical entity in the physical space and the digital twin model in the information space interact through the connection between the two, and the digital twin data contains all the information of the digital twin, running through the present-future, physical space-information space, physical entity- Digital twin model – connection interaction – function service. In addition, the physical entities, digital twin models, digital twin data, connection interactions, and functional services in Figure 1 have different levels of capability at each maturity level of the digital twin, but due to the limited information capacity of the picture, Figure 1 does not compare them. To expand and describe in detail, this part will be expanded in the third chapter .

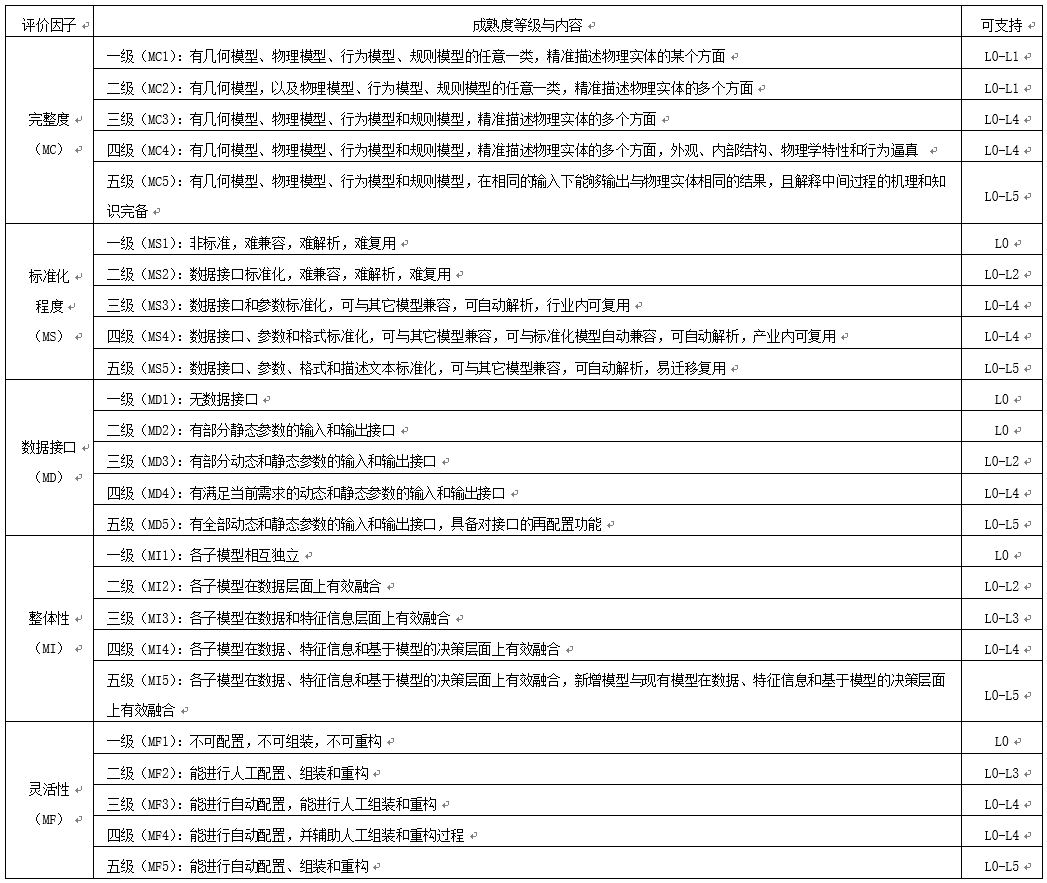

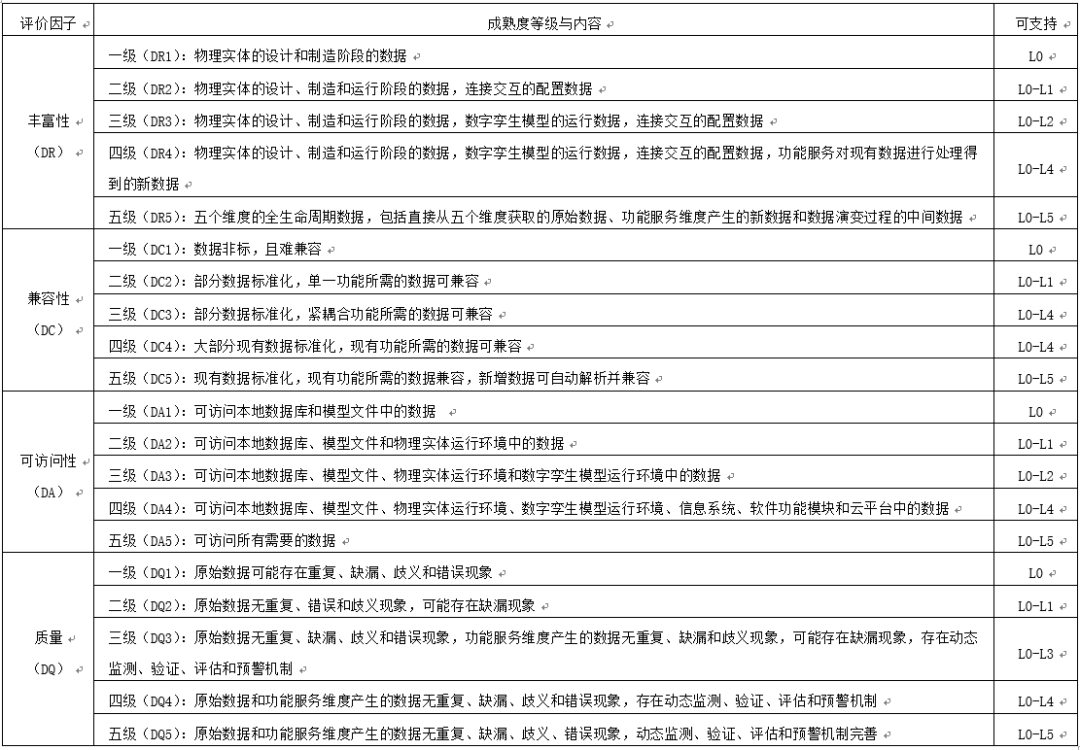

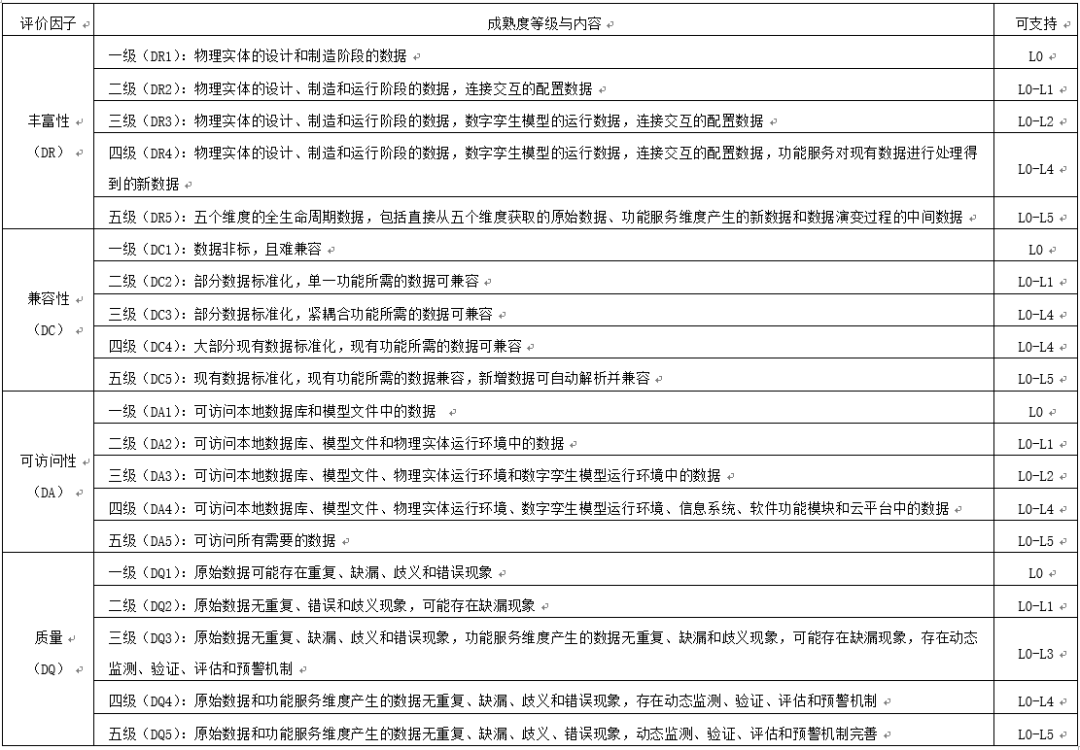

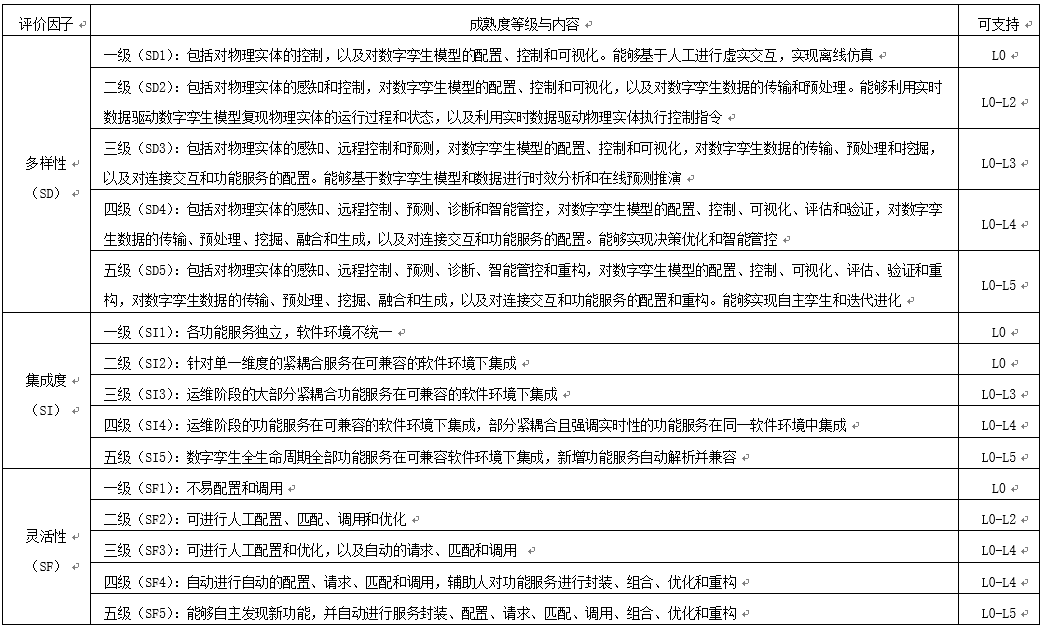

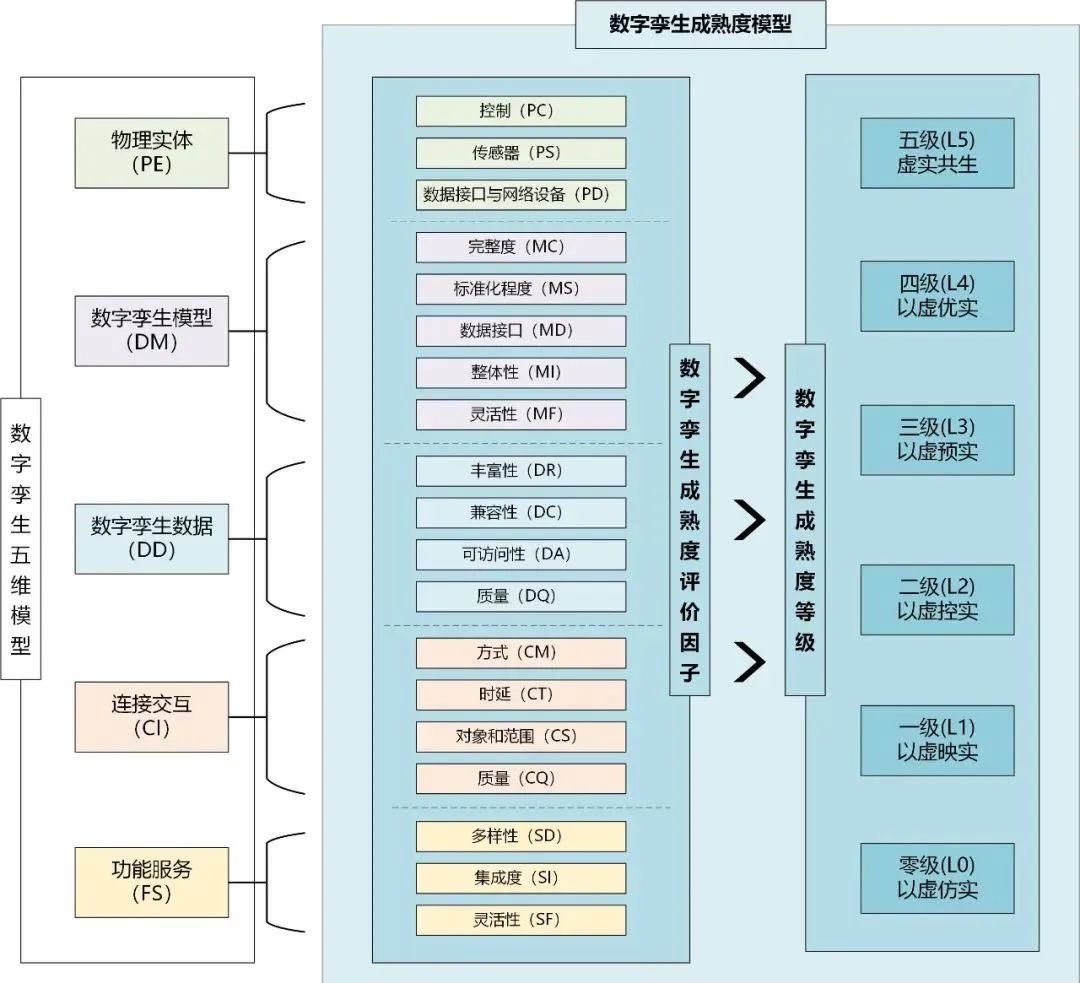

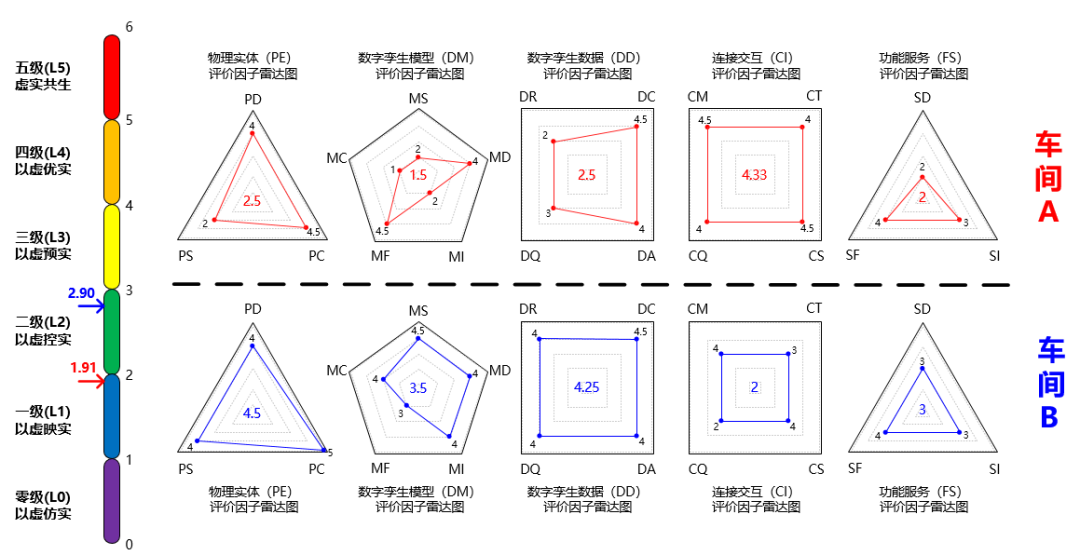

to simulate reality refers to using digital twin models to describe and characterize physical entities. Digital twins with this capability are at the zeroth level (L0) of their maturity levels. Those who meet this requirement Practices and applications can be classified under the concept of generalized digital twins. At this level, the digital twin model describes the unilateral or multiple attributes and characteristics of physical entities from one or more dimensions of geometry, physics, behavior, and rules, so that it can replace physical entities for simulation analysis or experiments to a certain extent. However, the real-time interaction between the digital twin model and the physical entity cannot be realized through direct data exchange, and it mainly relies on human intervention to achieve indirect virtual-real interaction, including the control of the physical entity and the control and update of the digital twin model. 2.2 Level 1 (L1): Mirroring reality 2.3 Level 2 (L2): Controlling the real 2.4 Level 3 (L3): Using the virtual to predict the real 2.5 Level 4 (L4): 2.6 Level 5 (L5): Virtual 3. Digital twin maturity evaluation factors The digital twin maturity level describes the conceptual category and ladder goals of digital twins from a macro perspective, as well as the evolution path of digital twins formed by the series of goals at each stage. In order to realize the operable digital twin maturity evaluation, from the five dimensions of physical entity, digital twin model, digital twin data, connection interaction and functional service, further analysis obtains 19 relevant factors that can affect the maturity level of digital twin . It is used as an evaluation factor for maturity grading, and the specific requirements for each maturity level of the digital twin for the maturity level of the evaluation factor are specified, as shown in Table 1 to Table 6.

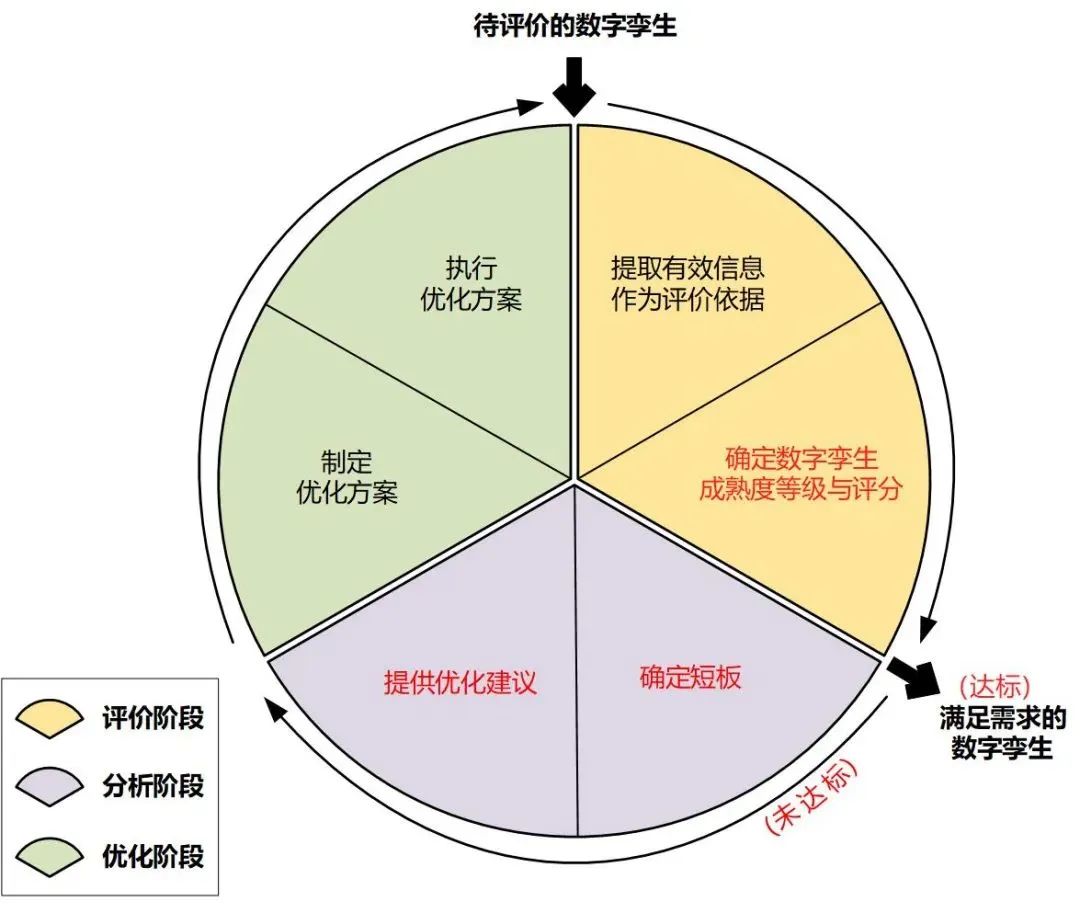

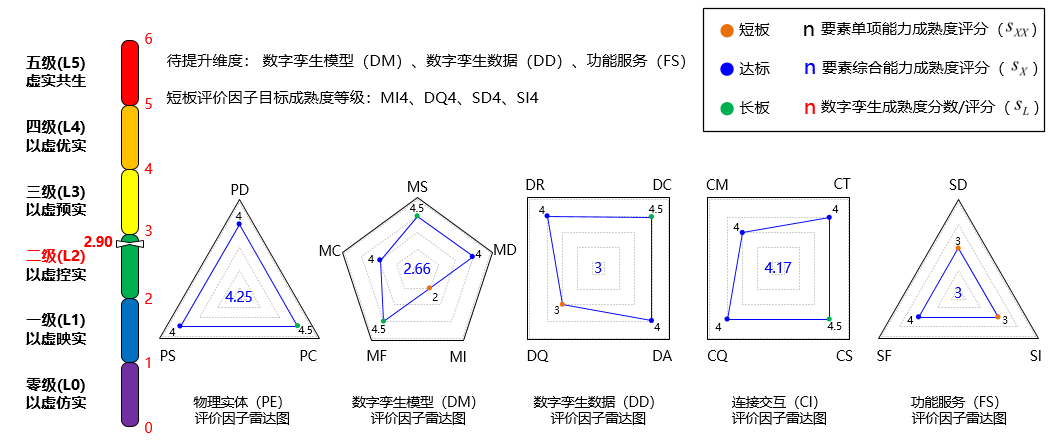

Table 1 Requirements for each maturity level of digital twin       The above digital twin maturity level and digital twin maturity evaluation factors constitute the digital twin maturity model , as shown in Figure 2. Among them, the digital twin maturity level systematically describes the conceptual category and phased goals of digital twin, as well as the capability characteristics of digital twin in each development stage, while the digital twin maturity evaluation factors include physical entities, digital twin models, The five subdivision dimensions of digital twin data, connection and interaction, and functional services sort out the different levels of capabilities required by digital twins at different maturity levels, laying the foundation for operable digital twin maturity evaluation.   In order to verify the digital twin maturity model and its application process proposed in this paper, the maturity evaluation of the unit-level digital twin (digital twin robot) and system-level digital twin (digital twin workshop) is carried out, respectively, as shown in Figure 4 and Figure 5 . Among them, the maturity evaluation results of the unit-level digital twin are used to guide its upgrade and optimization, and the maturity evaluation results of the system-level digital twin are used to compare the development levels of the two digital twin workshops.   and Maturity Evaluation Results of Digital Twin Workshop B Some final learning experiences: The Industrial Metaverse is not a technology. It is based on Internet technology and integrated network development. It is a new format of digital information ecological integration and development. It is a new set of technological upgrades. The Industrial Metaverse is a new industrial ecology based on the new organizational model in the scene, combined with modern visualization or XR technology, new information and communication technology represented by 3D digital twins, and the real industrial economy. Through technologies such as XR, AI, loT, cloud computing, and digital twins, we will open up seamless connections between people, machines, objects, and systems, realize the combination of digital technology and real industries, and promote the efficient development of physical industries. Therefore, we must do a good job in the concept of “ecology”, “open source”, and “service”. Metaverse is to break down the barriers of “chimneys”, realize the seamless connection of virtual people, “robots” and “things” in scenes, improve organizational efficiency, and improve organizational security. The industrial metaverse can be understood as the concept of the metaverse and the application of technology in industry, which is the qualitative change factor that empowers the industry and promotes industrial improvement, innovation, and even revolution. Fresh thinking is needed to raise awareness. The industrial metaverse will subvert the current economic and social structure, and different traditional industries will be reborn in the industrial metaverse, which is a historic opportunity for China’s manufacturing industry to overtake in a corner; opponents believe that the industrial metaverse is a concept The hype is still far away from the realization of the industrial metaverse, and the talk now is purely “creation out of nothing”; some people even believe that the industrial metaverse is an industrial utopia, a fiction that does not exist at all . I think the new ecology of virtual reality reconstruction of digital will not stop. At present, the digital twin application of the Metaverse is not only in the consumer field, but can promote the development of the industrial field. Recently Microsoft announced that Kawasaki Heavy Industries has become a new customer for its “Industrial Metaverse” business. Kawasaki Heavy Industries plans to let shop floor workers wear Microsoft HoloLens headsets to assist in production, maintenance and supply chain management. Microsoft’s industrial metaverse already has two important customers, Heinz and Boeing. The Microsoft HoloLens device actually reminds me of the Venus project nearly 20 years ago – which belongs to the smart home, and the Mediaroom system – which belongs to the IPTV system. Although neither of these two systems have become Microsoft’s “Golden Bull” products, they are at least directional in terms of industrial logic. What about the next metaverse platform? My personal opinion will be from being relatively closed to realizing the landing of the industrial metaverse in customized scenarios based on open source.After all, in addition to Microsoft, another technology giant, Nvidia, is also aiming at the “industrial metaverse”. Based on the Omniverse platform, AI and computing technologies, Nvidia can achieve the results of building an industrial metaverse. In addition to the current layout of “big factories”, we firmly believe that there are many large and small companies in professional fields in other ecological circles. However, the research on the digital twin maturity model of the industrial metaverse in this paper is worthy of in-depth study in practice. It is a very necessary way and a good guiding role in building a digital twin model. |

|

| Previous:The Insighter’s Cloud Lecture: Different people have different opinions | |

| Next:The digital transformation path of the whole life cycle of enterprises |